3D printing is an additive production method. A three-dimensional object is produced by adding multiple layers upon layers of material. Using modern 3D printers and a 3D model, one can 3D print almost anything.

It is revolutionizing countless industries that one is now able to produce complex parts that are literally impossible through traditional methods. It solves previously unimaginable levels of geometry and adaptations. All that is required is a 3D CAD drawing.

Using the additive process 3D printing, parts can be produced with the absolute minimum of waste. The rapid nature and efficiency of technology make this method ideal for modern industry and projects that cannot afford to wait, and that earn large sums on streamlining their processes.

What can you make with a 3D printer?

3D printing is very popular today. 3D printing is one of the most versatile production techniques available on the market today, and can be used in almost any industry. It is best to use this method in cases where a part or product is very complex in shape, such as lattice structures, or where internal detailing is required. 3D printing is also particularly suitable for fast production, of prototypes of plastic components either for direct use, or to verify designs.

Prototyping

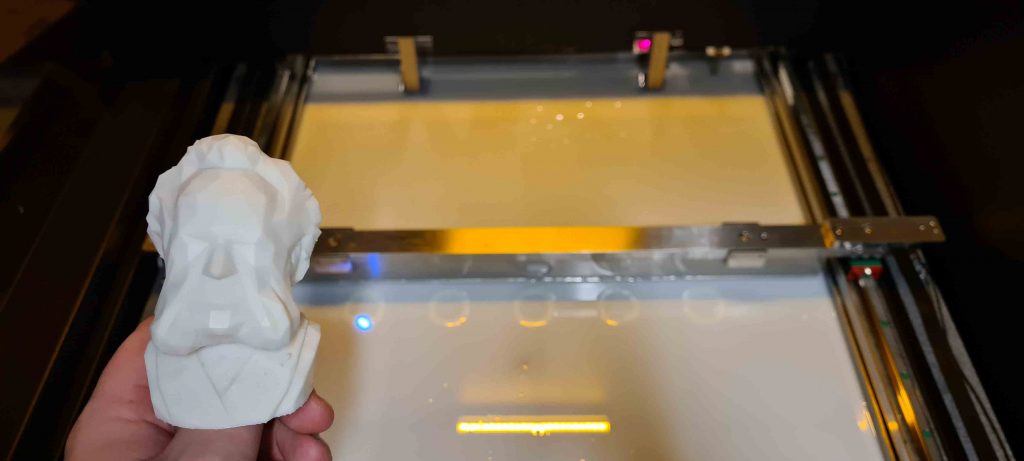

Using 3D printing, we have the opportunity to produce an almost identical copy of the product to be developed. It is therefore often used to make prototypes . Here you get the opportunity to get a prototype in high quality and test complex geometry before the actual production starts. This method also does not require a long time, so it is well suited as an intermediate stage to a further process - or as a product verification and design confirmation of your product.

Small series production or single component

Often a 3D printer can produce a finished complex product without the need for further assembly. This method is also useful for small series production, or single component production for custom needs and solutions where the component may be advanced or have a complex geometry. For example, only one or two prototypes, as there are no tool costs and no mold needs to be produced.

How to 3D Print?

If you do not have a 3D printer or a 3D model of what you want 3D printing, we at Mezonic can help you design and produce the product itself. Our expert team in 3D printing is ProtoFab. They offer fast prototypes and have Norway's largest capacity for 3D printing based on SLA technology. In recent years, we have made a major investment in 3D printing, and today have Norway's largest capacity for SLA printing. We currently have 6 machines for 3D printing - including 3 machines that can produce components up to 400x600x600 mm.

We 3D printer for companies in everything from automotive industry, medical technology, dentistry, art, fashion, electronics, industrial design, component production to footwear. In each of these segments, new production techniques lead to revolutionary improvements in efficiency, cost reduction, convenience and also open the door to completely new ways of thinking and production methods in industrial design and product development.

How does the process take place?

First, a detailed CAD file is created and imported into the 3D printer software. This software analyzes the CAD drawing and divides it into ultra-thin cross-sectional layers. An engineer will analyze the object to be printed and determine where the part needs support structure to be printed so that the structure can remain stable. This additional material is later removed after the actual printing process. The printheads are laser controlled and gradually build up the object by working along the thin cross-sections generated by the software. A wide range of materials are available, and on the material front, the offer is constantly increasing as the technology becomes more advanced.