Grepi Plast AS is a Norwegian plastic manufacturer that develops, designs and manufactures injection moulded plastic products. Grepi Plast was established in 1999 and purchased by Mezonic in 2014. They have a strong international customer base, including Schneider Electric, Georg Fischer, Bayer Health Care, Beerenberg Corp and Armaturjonsson AS.

Grepi Plast is based in Porsgrunn, Norway, co-located with the companies Pavels Innovation and Protofab. Here they develop and manufacture polymer-based technical components for industrial customers with their six production machines, including a 3-component casting machine.

Gripi Plast has developed and patented its own fastening plug system, a clamp for insulated pipes and a friction attachment for underwater systems. The clamp for pre-insulated corrugated pipes is the only one that does this job on the market. It caught the attention of Swiss firm Georg Fischer JRG AG, which later bought the legal rights and it approved the patent internationally.

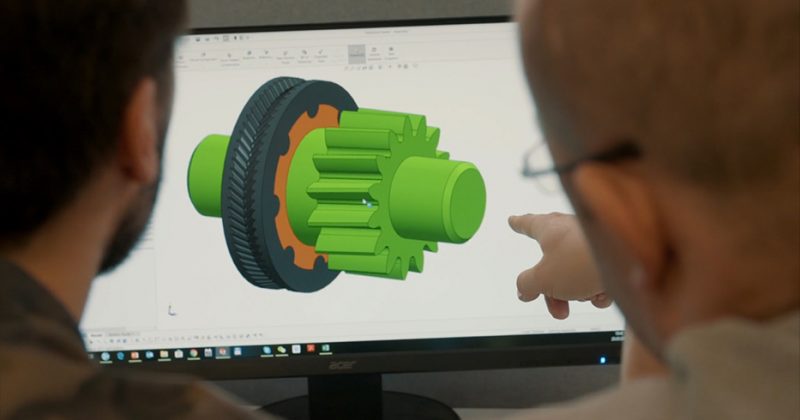

For many customers, Grepi Plast is a contributor during product development or product improvement. We have particular expertise in what is required for the products to be produced in large volumes at the right price and quality.

Grepi Plast is a centre of expertise in materials technology, and has special experience in choosing the right material to get the expected properties in a finished product. When we do not reach out, we involve our partner Norner AS, which is a global market leader in industrial R&D on polymers.

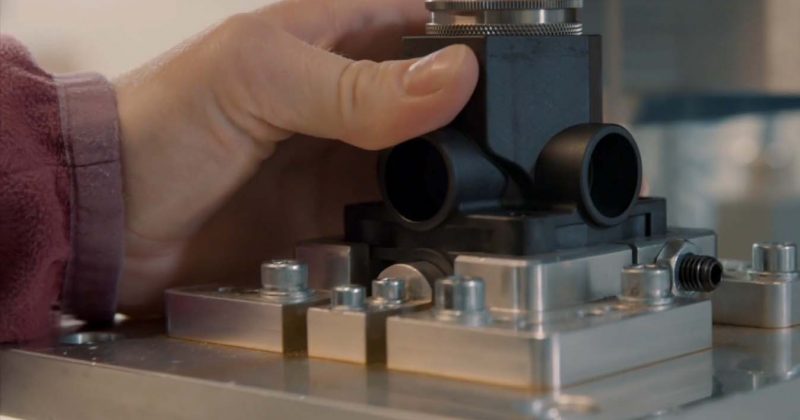

A good and stable production of large quantities over many years requires good form tools. Development of form tools is a separate subject and Grepi Plast has its own tool designer, in addition to working well with TK Nor AS. During this development, it is typically involved both from the product developers, the tool designer and those who will produce the products.

We have tools that have produced up to 12 million units in the same tool, but usually design the tools for a slightly more moderate number. The form tools we usually get produced in Norway, Sweden, Portugal or China.

The plastic manufacturer Grepi Plast produces quality technical products in advanced thermoplastic technology for furniture, catering, computer / electronics and pharmaceutical industry, to name a few.

A product often consists of many components. We can therefore also offer the final finish of the products we produce. For quality assurance of an approved and fully developed plastic product, weight and visual inspection are the main indicators to detect any quality deviations. We perform an accurate and daily monitoring of these parameters, and can also conduct regular microscopy studies of critical areas. Together with each customer, we agree on the level and scope of quality assurance.

Besides, we handle: marking, montage, component and system test and packing.

Gripi Plastic specializes in injection molding. At the factory in Porsgrunn we have eight casting machines where we can produce components from 0.5 grams to 250 grams, in series sizes from a few thousand to many millions. One of the machines is a 3-component machine, so we effectively produce products where several types of materials are included.

Moreover, we have close and well-functioning cooperation with manufacturers in Denmark and Asia, for cases where we do not have suitable machines or capacity, or where we want to use external expertise. At AVK Plast A/S in Denmark, we produce products with unit weight up to 11 kg, for our sister company Mezonic Recycling Solutions AS. To follow up and maintain good cooperation with our Chinese partners, we have our own engineer in China.

Products: Water stop valve for smart housing solution, distributor cabinet, div. components for Sanipex underfloor heating system

Services: Product development, development of approximately 25. form tools

Learn more

Product: Top and bottom cap for glass with their Xofigo radiation medicine.

Services: Product improvements. Development of form tools.

Learn more

Product: Fastening plugs

Relationship: Schneider Electric sell Grepi's fasteners under its own brand Thorsman, to electric wholesalers in several countries.

Learn more

Grepi manufactures parts for elekro installation – hospital equipment.

Gasket for water pipes – Xstream gasket.

Manufacture of plastic parts to the Elquick system. Elquick is Vik Ørsta's link system based on plug couplings. Used e.g. in the light master.

Specially trained dogs help Equinor and Gassco detect corrosion in piping systems. Grepi produced the plastic components of the system.

Production agreement with Georg Fischer AG. Grepi Plast has developed and patented new special clamps for insulated pipes.

+47 476 60 111

Hydrovegen 19, 3933 Porsgrunn.